Dohyun Machine Works “DMW” began operation in 2005.

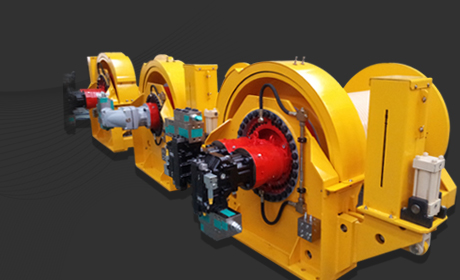

At first the main product was Spur Gears and Chain Wheels for winches.

DMW purchased 3 used Gear Cutting machines that have a capacity of :

Up to 72 inch diameter gears And Up to #1 DP cutters

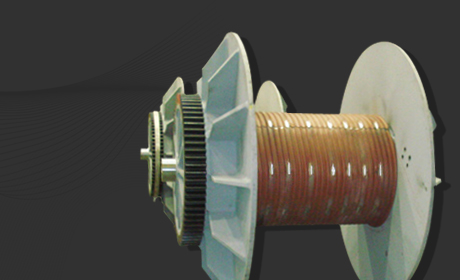

DMW purchased a larger shop (#3) and dedicated the facility to EDM Technology.

Installation of an outside slab area designed to round up Bull Gears, container rings and roller paths assure correct fit up and diameters are within tolerance.

Land area 2,310 Sq Meters

Shop area is 460 Sq Meters and is equipped with a 5 tonne crane.

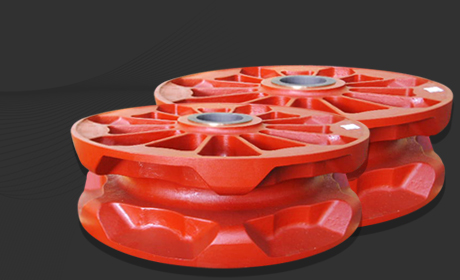

Supply of large Bull Gears using wire cutting “ EDM Technology ” was added to the range of products by DMW.

Gear cutting for small gears and chain wheels were subcontracted instead of in house manufacture. This allowed the shop space to become more efficient to produce and handle the large segmental bullgears.

DMW naturally branched out to the supply of the large roller paths and container rings for the offshore cranes of NOV AmClyde.

DMW also received orders to supply Main Hook Blocks and various weldments for the tackle and revolving systems for AmClyde cranes.

Developed DMW's facility expansion plan for the following 4 years (2009-2012) and have elected not to enter into engineering design. DMW’s base is that of a major sub - vendor for existing equipment suppliers. DMW does involve themselves in manufacturing design improvements and recommendations for material conversions.

In 2009 DMW purchased additional property. Total area of the property is 9,240 Sq Meters.

During this period DMW began manufacturing more major components for NOV AmClyde and some smaller structures for other customers.

DMW received their ISO 9001 certification with ABS in 2010.

In 2011 DMW purchased an adjoining property with a total land area is 6,500 Sq. Meters.

The EDM Wire Cutting was moved from #3 shop to #7 shop.

This shop is total of 160 sqm and has a 5 Ton Crane.

Number 3 Shop was then upgraded with a 15Ton/10Ton new crane and runway.

The existing 5 Ton is on the high crane runway.

During this year DMW main Customer was NOV Hydralift AmClyde and we continued

supply of our Main Product Base items.

Number 3 Shop was designated as the second machine shop and houses the SNK 3N Planar miller and the Toshiba 2M Dia Veritcal Lathe.

Adding of the machines allowed more in house machining and control for DMW Main

Product Base items.

NKT joint project for Plate Leveler for Hyundai Steel in Korea

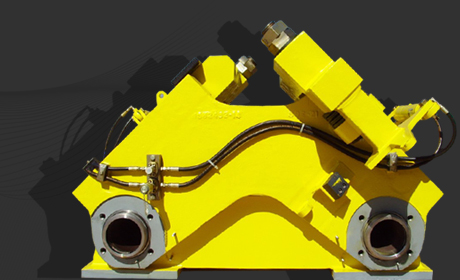

Equatorial Inc. in Singapore for small mooring system Chain Stoppers.

Yanase Inc. Korea for Dredge Crane parts

NOV Norway for some handling assembly’s

American Equipment Singapore

PH Hydraulics Singapore

NOV sales went down and so DMW main customer base was very low and we had to

downsize our labor force accordingly but maintained our experienced office staff and

main shop personnel.